Professional hot melt glue equipment basically has three components for melting the glue.

Hot melt unit

The hot melt unit forms the basis of the system. For large systems, a drum melter or drum melter is sometimes used, these melt barrels of 20 or 200 liters. Most standard systems are tank systems with a capacity of 4, 8 or 10 liters.

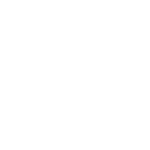

The hot melt unit is also equipped with a glue pump, a distribution unit and a control unit.

Hot melt hoses

Hot-melt hoses are heated hoses that feed the hot-melt under high pressure to the hot-melt glue head.

Hot melt adhesive head

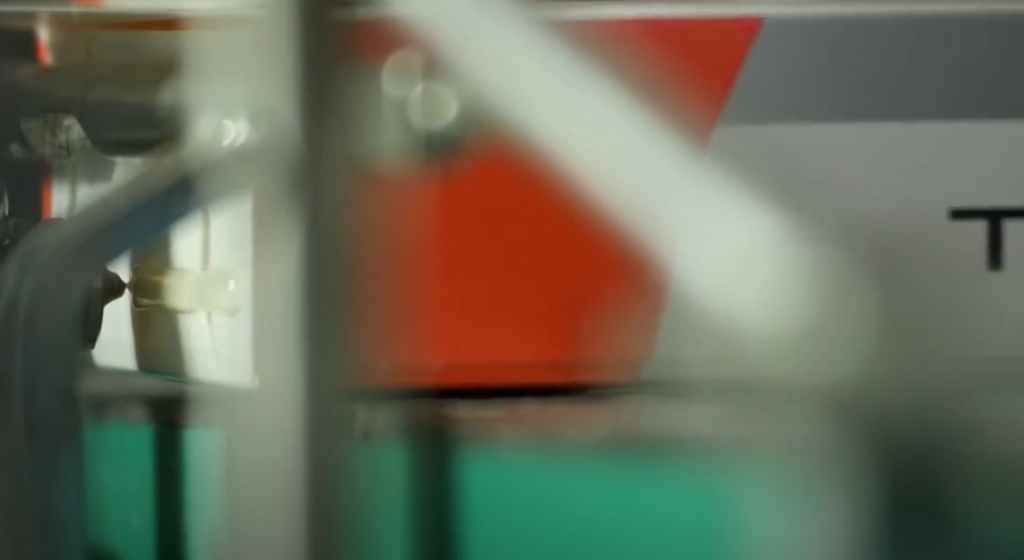

The hot melt glue head is the most refined and possibly most important part for your application. Here you can opt for a line bonding, circle pattern or flat coating. The glue heads themselves are standard air-opened and spring-closed (air-switched), but for fast applications, fully electrically controlled glue heads are also used.

Glue rollers

Instead of a contactless high pressure application, applications can also be executed with a hot melt glue roller.

Coating nozzle

The coating nozzle, also known as slot-die-coater, is also suitable for applying flat layers of glue, such as a self-adhesive strip on shipping boxes.